Unlocking the Power of Aluminum Busbars for Modern Electrical Systems

In today’s rapidly evolving electrical and energy industries, aluminum busbars have emerged as a reliable and efficient solution for power distribution systems. Known for their lightweight, cost-effectiveness, and high conductivity, aluminum busbars are increasingly replacing copper in both commercial and industrial applications. At AP Precision Metals, we provide custom aluminum busbar solutions backed by advanced manufacturing techniques and a deep commitment to precision, efficiency, and long-term performance.

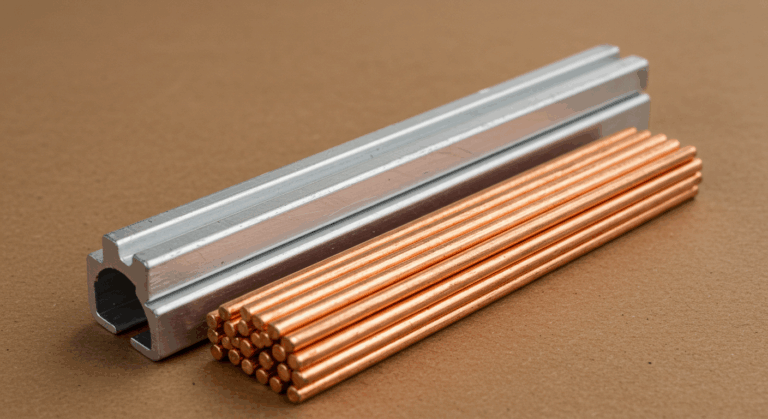

What Are Aluminum Busbars?

Aluminum busbars are solid metal strips or bars made from high-grade aluminum, designed to conduct electricity within electrical distribution systems. Their primary role is to carry large current loads across electrical components with minimal resistance. Unlike traditional wiring, busbars provide a compact and organized way to manage high-capacity current flow, especially in environments like switchgear assemblies, battery banks, power panels, and energy storage systems.

At AP Precision Metals, we specialize in fabricating aluminum busbars that meet the specific needs of clients across a wide range of industries. Whether it’s a high-voltage application or a compact power system design, our custom solutions offer flexibility, durability, and superior performance.

Advantages of Choosing Aluminum Busbars

1. Lightweight Yet Strong

Aluminum is approximately one-third the weight of copper, making it an ideal material for applications where weight reduction is critical. This lighter weight simplifies installation, reduces support structure requirements, and can lower overall system costs without compromising structural integrity or performance.

2. Cost-Effective

Compared to copper, aluminum is more abundant and less expensive. This price advantage makes aluminum busbars a smart choice for projects where budget control is essential, especially for large-scale electrical installations. The material cost savings can be substantial without sacrificing functionality or reliability.

3. High Conductivity and Performance

While copper has a slightly higher conductivity, aluminum’s conductivity-to-weight ratio is superior. AP Precision Metals uses top-tier electrical-grade aluminum alloys, such as Chalco conductive aluminum, which ensures consistent electrical performance, reduced resistance, and long-term reliability.

4. Corrosion Resistance

Modern aluminum busbars are engineered to resist corrosion in challenging environments. Surface treatments, anodizing, and advanced insulation options add further protection, especially in marine, outdoor, or industrial settings with exposure to moisture or chemical agents.

5. Sustainability and Recyclability

Aluminum is one of the most recyclable metals on Earth. The manufacturing and recycling processes require significantly less energy compared to copper, contributing to a lower carbon footprint. Choosing aluminum busbars helps businesses meet sustainability goals without compromising performance.

Custom Aluminum Busbar Solutions from AP Precision Metals

We understand that no two electrical systems are alike. That’s why AP Precision Metals offers a wide array of custom aluminum busbar solutions designed to meet your unique electrical, mechanical, and spatial requirements. Our capabilities include:

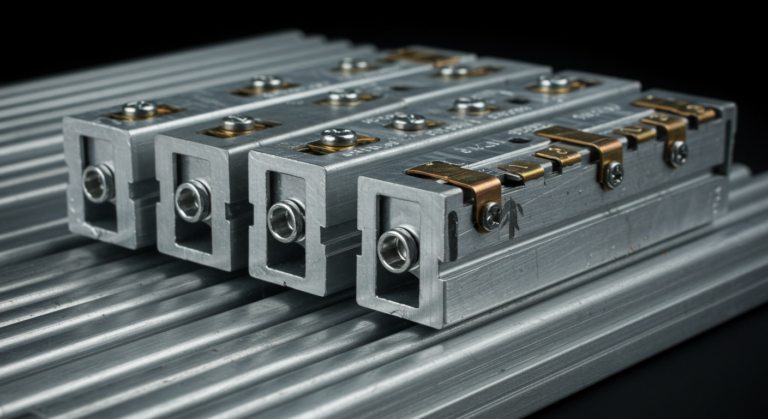

- Flat aluminum busbars – Ideal for traditional power distribution needs

- Extruded aluminum busbars – Provide design flexibility and strength

- Laminated and insulated busbars – Enhance safety and reduce electromagnetic interference

- Precision CNC machining – Ensures tight tolerances and repeatability

Our engineers work closely with clients during the design and prototyping stages to ensure optimal performance and seamless integration with your existing systems.

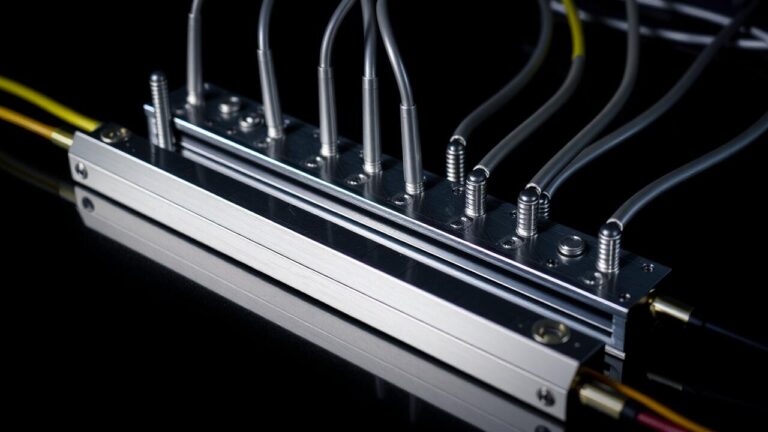

Precision Manufacturing for Maximum Efficiency

At AP Precision Metals, we integrate advanced fabrication methods to elevate the quality and performance of our aluminum busbars. Our in-house capabilities include:

Laser Welding and Cutting

Laser technology allows for extremely precise and clean welds and cuts, reducing resistance at connection points and improving conductivity throughout the busbar system.

Automated Stamping and Bending

We utilize automation to ensure uniformity and efficiency across high-volume production runs, reducing labor costs and turnaround times without sacrificing quality.

Cold Spray and Surface Treatments

Advanced techniques like cold spray coating enhance the conductivity and corrosion resistance of aluminum busbars, making them suitable for critical and harsh environments.

Insulation and Plating Options

Our insulation techniques improve safety and thermal performance, while options like tin or silver plating offer enhanced conductivity and protection from oxidation.

Design Considerations for Aluminum Busbars

When designing aluminum busbars, several factors must be carefully evaluated to ensure optimal performance and durability. Our engineering team at AP Precision Metals takes into account:

- Current-carrying capacity – Based on expected loads, ambient temperature, and required ampacity

- Thermal performance – Ensuring effective heat dissipation to prevent overheating

- Mechanical strength – To withstand environmental stress and vibration

- Spacing and layout – Reducing electromagnetic interference and ensuring proper insulation

- Fabrication precision – CNC-machined designs ensure accuracy and compatibility with terminal connections

Our comprehensive approach ensures that each aluminum busbar we deliver is not only built to specification but also optimized for the demands of your specific application.

Applications Across Industries

Aluminum busbars from AP Precision Metals are trusted by clients in a wide range of industries, including:

- Renewable energy systems – Solar and wind power infrastructure benefit from aluminum’s lightweight and corrosion-resistant properties

- Electric vehicles (EVs) – Battery banks and power electronics require compact, efficient, and lightweight busbar solutions

- Power distribution units – Industrial and commercial electrical panels use aluminum busbars for effective energy routing

- Telecommunication and data centers – High-current aluminum busbars support uninterrupted power for mission-critical operations

- Marine and aerospace – Lightweight aluminum components contribute to fuel efficiency and weight savings

Why Aluminum Busbars Are the Future

As the world continues to shift toward electrification and energy efficiency, aluminum busbars are playing a critical role in enabling sustainable, scalable, and high-performance power systems. Their recyclability, cost-effectiveness, and compatibility with new technologies like smart grids and EV infrastructure make them a forward-thinking choice for businesses and manufacturers alike.

At AP Precision Metals, we stay ahead of trends by continuously investing in R&D and upgrading our manufacturing processes. From initial consultation through to prototyping and full-scale production, we provide clients with reliable, future-ready aluminum busbar solutions.

Partner with AP Precision Metals for Your Aluminum Busbar Needs

When precision, performance, and partnership matter, AP Precision Metals delivers. Our team is ready to help you design and manufacture aluminum busbars tailored to your exact requirements. Whether you’re upgrading an existing system or launching a new energy solution, we’ll support your project every step of the way.

Contact us today to discuss your aluminum busbar needs and see how our custom solutions can enhance your electrical systems.