Busbar Inspection: Ensuring Reliability and Safety in Electrical Systems

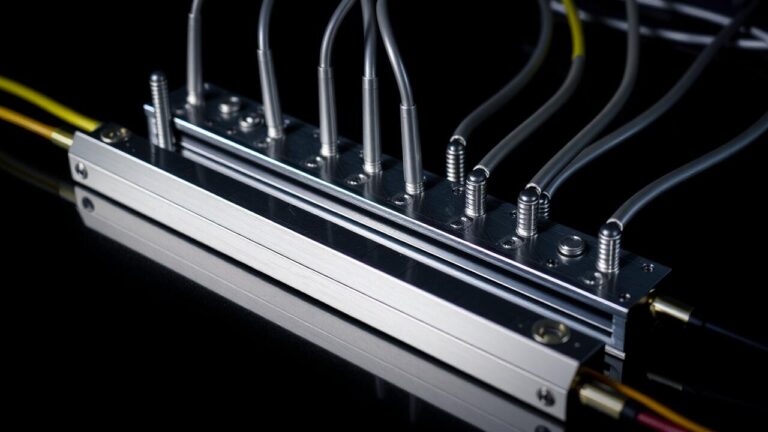

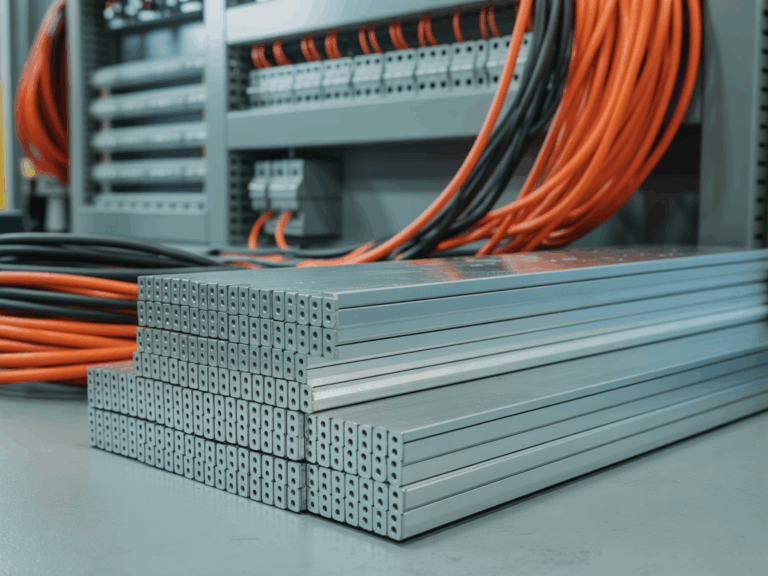

Busbar inspection is a critical maintenance process that ensures electrical distribution systems remain safe, efficient, and reliable. Busbars—solid strips of conductive metal such as copper or aluminum—are essential components in switchgear, panel boards, and power distribution systems. Over time, environmental factors, electrical loads, and mechanical stresses can impact their performance. Regular inspection helps identify issues early, preventing costly downtime and potential safety hazards.

Why Busbar Inspection Is Important

Busbars carry significant electrical current and are subject to heat, vibration, and environmental exposure. Without routine inspections, small issues can escalate into major problems. The benefits of regular busbar inspection include:

- Preventing electrical faults that can lead to equipment failure.

- Identifying corrosion, wear, or physical damage early.

- Ensuring optimal conductivity and energy efficiency.

- Reducing the risk of overheating and electrical fires.

- Maintaining compliance with safety and industry standards.

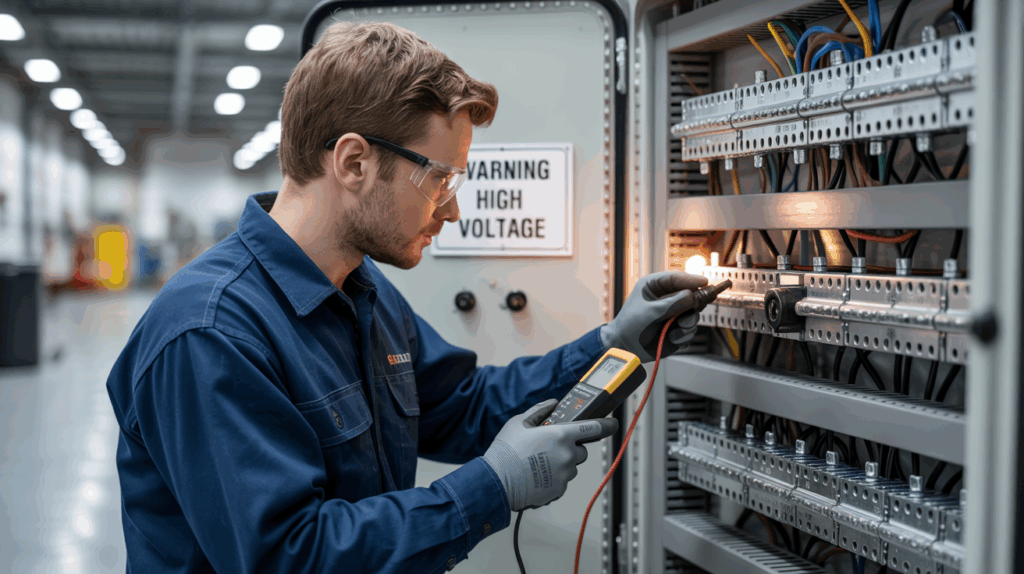

Key Elements of a Busbar Inspection

A thorough busbar inspection typically includes:

- Visual examination – Checking for discoloration, cracks, or physical damage.

- Thermal imaging – Detecting hotspots that indicate poor connections or excessive resistance.

- Connection checks – Ensuring all bolts, clamps, and joints are tight and secure.

- Corrosion assessment – Inspecting for oxidation or galvanic corrosion, especially in mixed-metal systems.

- Insulation testing – Measuring insulation resistance to prevent short circuits or arcing.

Common Issues Found During Busbar Inspections

Some of the most frequent problems uncovered include:

- Loose or deteriorated connections causing increased resistance.

- Corrosion reducing conductivity and structural integrity.

- Overheating from excessive loads or poor ventilation.

- Mechanical wear from vibration or improper installation.

- Contamination from dust, moisture, or other environmental factors.

How Often Should Busbar Inspections Be Performed?

The frequency depends on the operating environment and load demands:

- Industrial facilities – At least annually, or more often in high-demand applications.

- Commercial buildings – Every 1–2 years, depending on load and environmental conditions.

- Critical infrastructure – More frequent inspections, often quarterly, to ensure uninterrupted service.

Best Practices for Busbar Inspection

- Document inspection results for future reference and trend analysis.

- Perform inspections during scheduled maintenance windows to minimize downtime.

- Use qualified personnel familiar with busbar systems and safety protocols.

- Address any issues immediately to prevent further damage.

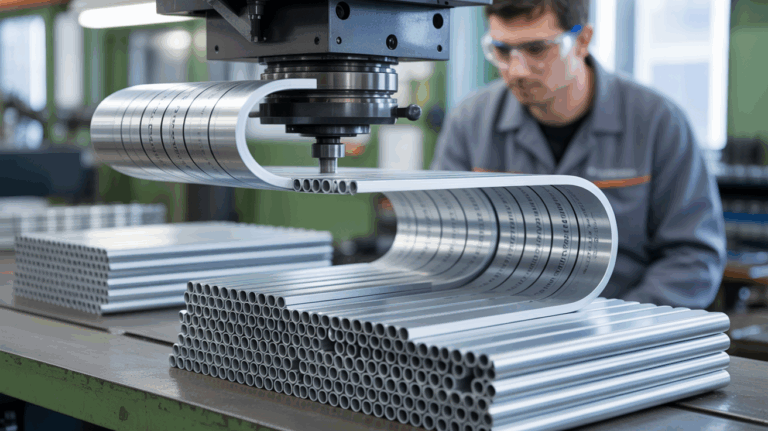

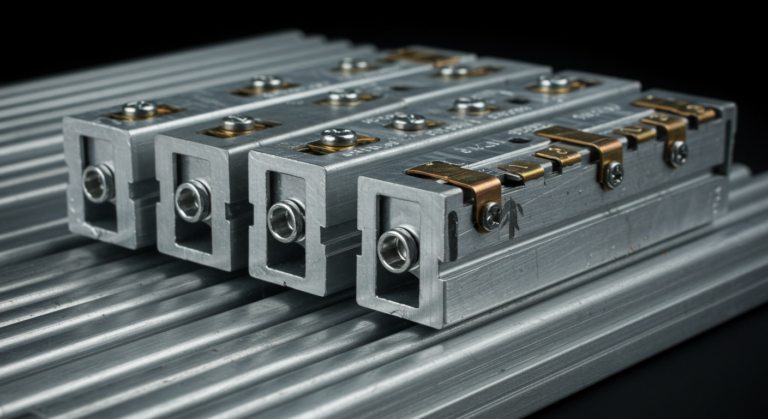

AP Precision Metals and Busbar Quality

While regular inspections are essential, starting with high-quality busbars is equally important. At AP Precision Metals, we manufacture precision copper and aluminum busbars designed for long-lasting performance in demanding environments. Our products are fabricated to exact specifications, ensuring consistent conductivity, durability, and resistance to environmental factors.

Partner with AP Precision Metals for Busbar Solutions

Whether you’re installing new busbars or maintaining existing systems, AP Precision Metals provides the expertise, materials, and precision manufacturing you need. By combining high-quality fabrication with proper inspection practices, you can maximize the lifespan and reliability of your electrical distribution systems.

Contact us today to learn more about our busbar manufacturing capabilities and how we can support your maintenance and inspection needs.