Aluminum Busbars vs. Copper: Which Is Right for Your Project?

When planning an electrical system—from industrial plants to power cabinets—a foundational decision you’ll face is the choice between aluminum busbars and copper busbars. Both materials are widely used, but they offer distinct benefits and trade‑offs. At AP Precision Metals, our expertise in high‑volume aluminum busbar manufacturing positions us to guide you toward the option that best meets your project’s performance, cost, and sustainability goals.

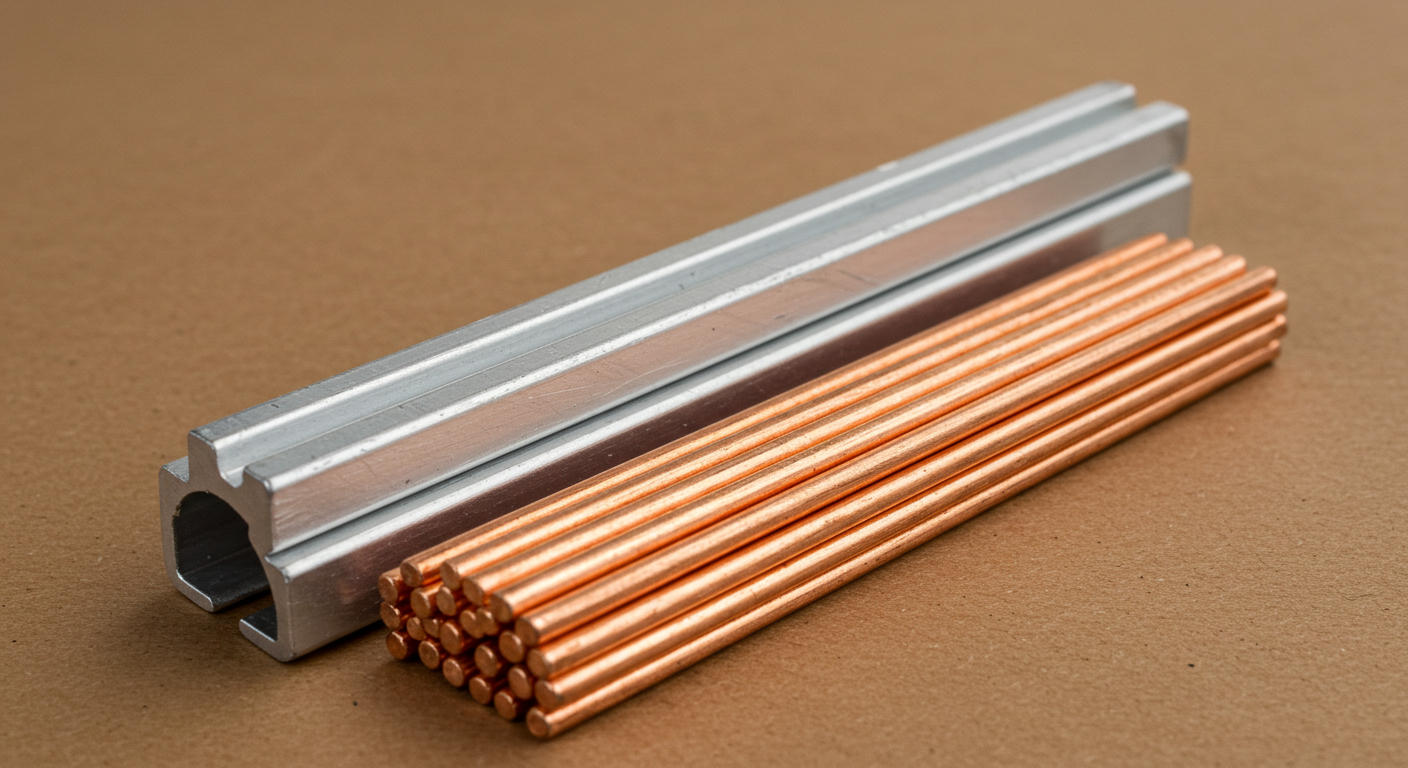

Understanding Aluminum Busbars

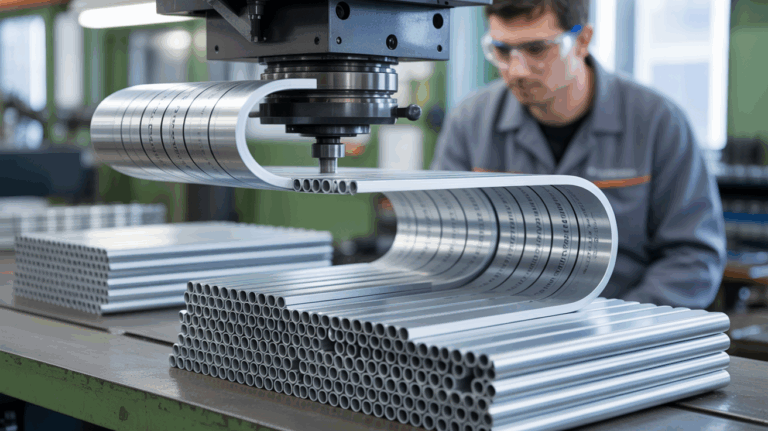

Aluminum busbars are electrical conductors made from sheet and plate aluminum, carefully processed to deliver reliable current transmission in energy systems. AP Precision excels in producing custom aluminum busbars at scale. For example, our 40,000‑square‑foot facility leverages advanced fiber lasers and best‑in‑class forming machines to process more than 75,000 lbs of aluminum busbar per month. :contentReference[oaicite:0]{index=0}

Key advantages of aluminum busbars, as highlighted across our site, include:

- Cost‑effectiveness – Aluminum is generally less expensive than copper, both in raw material and processing costs. :contentReference[oaicite:1]{index=1}

- Lightweight design – Aluminum’s lower density makes handling, installation, and mounting easier, translating to reduced labor and support requirements. :contentReference[oaicite:2]{index=2}

- Corrosion resistance & sustainability – Aluminum naturally forms a corrosion-resistant oxide layer and is highly recyclable, supporting long-term durability and environmental goals. :contentReference[oaicite:3]{index=3}

- Efficient power distribution – Although aluminum has somewhat lower conductivity than copper, design adjustments—like increasing cross-sectional area—can offset this without compromising performance. :contentReference[oaicite:4]{index=4}

Why Copper Still Dominates in Certain Applications

Copper has long been the default for high‑performance busbar systems—and for good reason:

- Higher conductivity – Copper has a superior electrical conductivity, which means smaller cross‑sections can handle the same current load more efficiently. :contentReference[oaicite:5]{index=5}

- Robust mechanical properties – Copper is stronger and better at withstanding mechanical stresses, vibrations, and thermal cycling—ideal for demanding or compact systems. :contentReference[oaicite:6]{index=6}

- Proven reliability – Copper busbars have decades of established performance across critical infrastructure and high‑density applications.

Key Design Considerations: Aluminum vs. Copper

Choosing between aluminum and copper boils down to specific project needs. Here are the critical factors to evaluate:

1. Electrical Load & Current Density

Copper’s higher conductivity means it needs less cross‑sectional area for a given current. However, for many large‑scale systems, increasing aluminum’s cross‑section is still a cost‑efficient approach. :contentReference[oaicite:7]{index=7}

2. Weight & Handling

Aluminum is much lighter, making it easier to install—especially valuable for retrofit jobs or where support structures are weight‑sensitive. :contentReference[oaicite:8]{index=8}

3. Cost Pressure

Material cost and processing efficiency often make aluminum a more budget‑friendly choice—though copper can win out in systems requiring compact precision. :contentReference[oaicite:9]{index=9}

4. Environmental & Corrosion Factors

Aluminum’s corrosion resistance, paired with its recyclability, make it an excellent choice for enduring, eco-conscious designs. Copper can require more rigorous corrosion management in harsh environments. :contentReference[oaicite:10]{index=10}

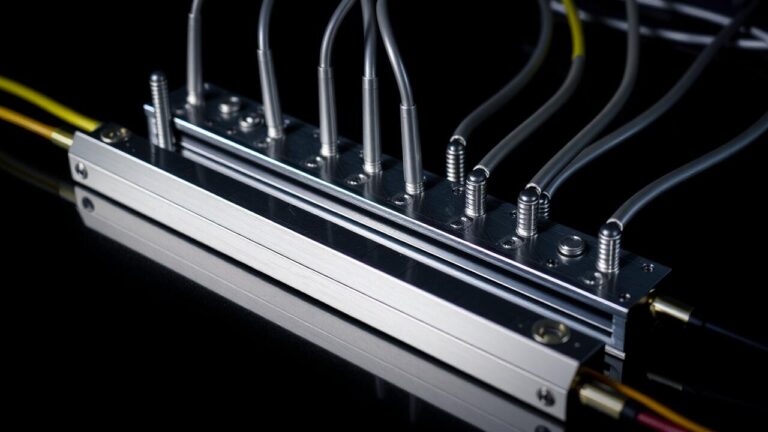

5. Fabrication Flexibility

At AP Precision, our custom aluminum busbar services include precision cutting, bending, and finishing—powered by state‑of‑the‑art fiber lasers and forming equipment. :contentReference[oaicite:11]{index=11} Copper fabrication can be more labor‑intensive and costly due to material hardness.

6. Thermal Expansion & Joint Integrity

Aluminum and copper have different expansion rates; aluminum expands more with temperature. Designs using aluminum must account for expansion and choose joint solutions that remain tight and reliable under cycling. :contentReference[oaicite:12]{index=12}

When Aluminum Is the Right Choice

Aluminum busbars are a compelling option when your project spans high currents, weighed heavily on cost control, or demands ease of installation and sustainable materials. They shine in applications like:

- Large-scale power distribution systems

- Energy transition projects (e.g., renewable integration, EV charging infrastructure)

- Retail and industrial switchgear where size and weight matter

- Retrofits that benefit from lightweight handling

AP Precision’s high‑output facility and expertise in aluminum busbar manufacturing make it easy to scale production without sacrificing quality. :contentReference[oaicite:13]{index=13}

When Copper Remains the Preferred Solution

Copper still dominates when:

- Space is limited and high current density is critical

- Maximum conductivity and minimal voltage drop are essential

- Applications demand superior mechanical strength and compact configurations

Aluminum or Copper: What Should You Choose?

Choose aluminum if your priorities include cost savings, lighter weight, high-volume production, and sustainability—especially when slight conductivity differences can be offset through design.

Choose copper if you need the utmost electrical performance in compact spaces, superior mechanical ruggedness, or long-proven resilience under demanding conditions.

With any choice, precise busbar design remains paramount. Factors like correct cross-sectional area, proper joint design, thermal management, and fabrication quality can dramatically affect performance. At AP Precision, we understand those nuances.

How AP Precision Metals Helps You Make the Right Call

As a national leader in aluminum busbar manufacturing, AP Precision offers:

- Immediate expertise in both aluminum and copper busbar fabrication, so you always get the optimal material. :contentReference[oaicite:14]{index=14}

- High-volume processing using fiber lasers and precision forming in our 40,000 sq ft facility, delivering throughput of 75,000 lbs per month. :contentReference[oaicite:15]{index=15}

- Custom design support to ensure the ideal balance of conductivity, cost, and durability. :contentReference[oaicite:16]{index=16}

Conclusion

There’s no one-size-fits-all answer when choosing between aluminum and copper busbars. The best choice depends on your project’s specific electrical, mechanical, and economic requirements. At AP Precision Metals, we bring the data, fabrication skills, and service capabilities to guide you to the right solution—whether that’s a lightweight aluminum design or a compact copper solution.

Contact us via our Contact Us page to discuss your project’s needs. Let us help you determine which busbar material—aluminum or copper—delivers the right performance, value, and reliability for your application.