Aluminum Busbars California – Local Supply & Delivery

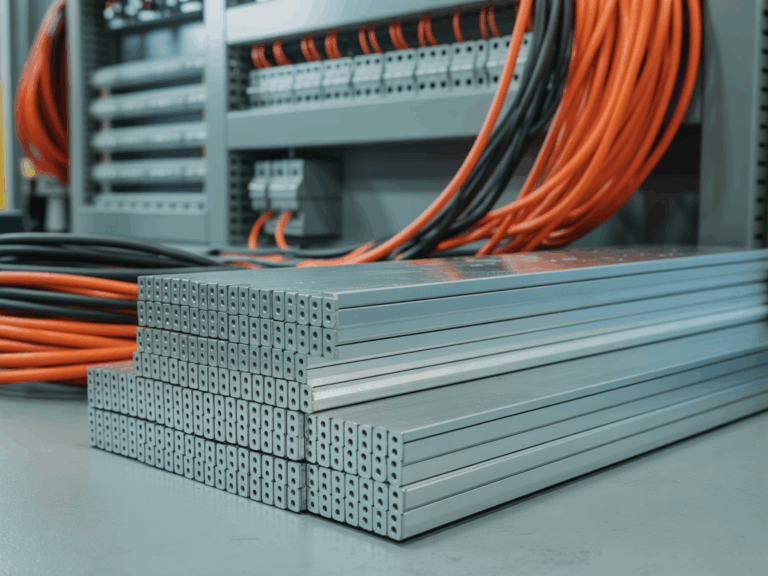

Aluminum busbars in California serve as essential components within electrical systems, enabling efficient power distribution across various applications. These bus bars are designed to replace traditional copper conductors, offering advantages such as lightweight construction and improved thermal management. As industries adopt more sustainable practices, the demand for quality conductors near you, including aluminum busbars, has increased. These bus ducts play a vital role in connecting electrical panels and facilitating the transportation of electricity, making them integral to modern electrical infrastructures. Manufacturers in California focus on delivering high-performance bus bars that meet diverse specifications, ensuring reliability and safety in electrical applications.

Aluminum Busbars in California | Quality Conductors Near You | Significance of Aluminum Busbars in Electrical Systems

Aluminum busbars play a crucial role in electrical systems by facilitating efficient power distribution. Their lightweight nature, compared to steel or stainless steel, simplifies installation in various vehicles, including trucks and electric vehicles. The use of aluminum alloys in these busbars enhances conductivity while maintaining durability. In California, where the demand for quality conductors is high, aluminum busbars are favored due to their effectiveness and performance in metalworking applications, including milling and fabrication.

The significance of aluminum busbars extends to their versatility across numerous industries. They are increasingly used in manufacturing processes that require extruded aluminum for structural integrity and reduced weight. This makes them ideal for applications in modern trains and vehicles, where energy efficiency is paramount. Finding quality conductors near you in California ensures that these aluminum busbars meet stringent performance standards essential for reliable electrical systems.

Common Applications of Aluminum Busbars

Aluminum busbars are integral in various sectors ranging from the aerospace industry to automotive applications. These conductive elements effectively distribute electrical loads across machinery, ensuring reliable performance in environments such as elevators, electronic components, and printed circuit boards. Their lightweight nature makes them ideal for use in carts and other mobile machinery, while adherence to quality control standards ensures they meet the rigorous demands of industries like aerospace.

The versatility of aluminum busbars allows them to be incorporated in metal fabrications for diverse applications, including instrumentation and pipe insulation systems. Their ability to handle significant electrical loads while maintaining conductivity makes them a preferred choice for electrical installations. For those searching for Aluminum Busbars in California and seeking quality conductors near them, options abound to cater to various industrial needs, guaranteeing durability and efficiency across multiple sectors.

Understanding Aluminum Bus Bar Manufacturing

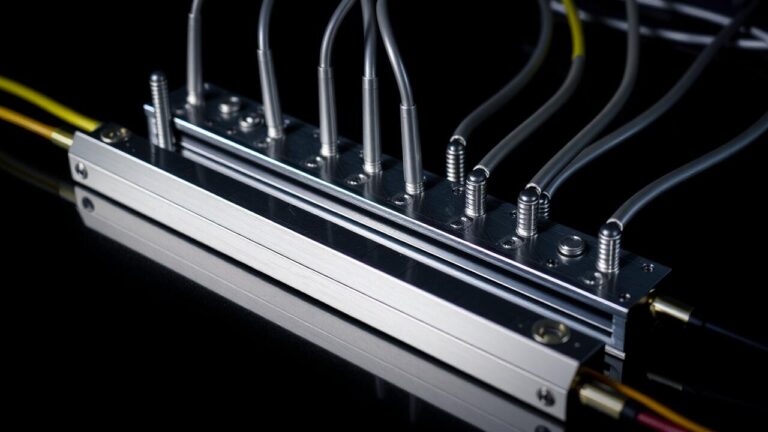

The manufacturing of aluminum busbars in California relies on precision and advanced technologies to produce high-quality aluminum busbars tailored for various applications. Machines used in the process are designed to shape and mold electrical-grade aluminum busbars that ensure excellent electrical conduction for sufficient wattage transfer. Conductive aluminum busbars serve as critical components in electrical systems, including engines and electronic circuit boards, where efficient transmission is paramount. Quality conductors near you often emphasize the importance of using durable and lightweight materials, enabling easier installation alongside other electrical components and wires. A focus on producing robust conductive aluminum busbars guarantees that these solutions meet the demands of modern electrical systems while maintaining reliability and safety.

Key Processes in Creating Conductive Aluminum Busbars

The creation of conductive aluminum busbars involves several critical processes that ensure the final product meets specific aluminum busbar specifications and performance standards. Different aluminum busbars are designed for various applications, with manufacturers often producing high-grade aluminum busbars that provide optimal conductivity and strength. The selection of the right aluminum busbar depends on factors such as load capacity and environmental conditions, making it essential to understand the unique characteristics of aluminum grade busbars available in the market.

During the manufacturing process, quality control measures play a significant role in achieving consistency and reliability. Custom aluminum busbars, including custom-shaped aluminum busbars, are tailored to meet specific client requirements, ensuring that the final product aligns with the intended use. Various aluminum busbar options are available, allowing customers to select aluminum bus bars that are not only functional but also fit seamlessly into their electrical systems. Aluminum Busbars in California | Quality Conductors Near You can guide buyers in finding reputable manufacturers that produce durable and efficient busbars for their specific needs.

Quality Control Measures in Production

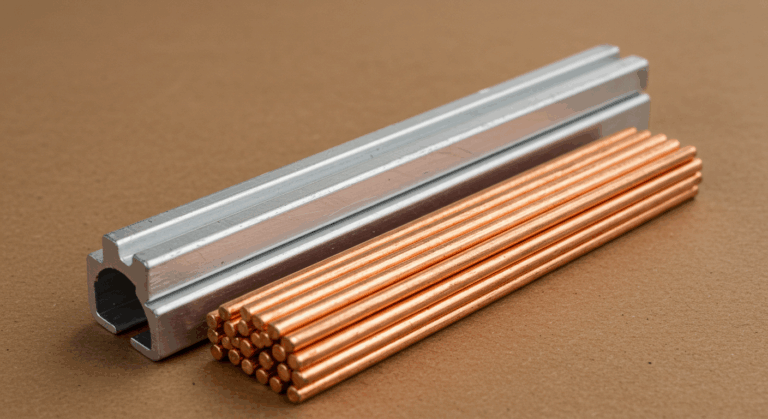

Quality control is paramount in the production of aluminum busbars in California. Manufacturers focus on sourcing aluminum busbars crafted from top-grade aluminum alloys to ensure optimal performance. This includes careful examination of aluminum busbar grades and rigorous testing of busbar components to meet industry standards. Distributors of bus bars, including flexible busbars and aluminum busbars, adhere to strict guidelines to maintain the quality of their products. The use of graziadio gda busbars with aluminum or copper conductors can enhance efficiency in various busbar applications.

There is a significant emphasis on monitoring the manufacturing processes to guarantee the production of high-quality aluminum bus bars. Southern busbars suppliers often implement standardized procedures for the creation of both square copper busbars and aluminum bus pipe, ensuring consistency across all products. The commitment to quality extends to offering superior bus bars that can withstand demanding electrical loads. Copper busbars are also scrutinized to ensure they meet the same high standards expected of aluminum products, providing customers with reliable electrical solutions. Quality conductors near you will typically highlight their dedication to maintaining these high-quality standards.

Advantages of Using Aluminum Busbars

Aluminum busbars in California are essential for various electrical systems due to their lightweight nature and durability. These components come in several forms, including rigid busbars, flexible busbars, and even extra-large busbars, making them suitable for a wide range of applications. Northern busbars suppliers offer an array of options, from insulated and grounding busbars to laminated bus bars and silver plate busbars. For those looking for customized solutions, distributors of flexible busbars can help organizations create their own busbars tailored to specific needs. Quality conductors near you ensure that busbar terminals maintain high standards of performance while providing reliable conductivity and load capacity, making aluminum a preferred choice over copper busbar options for many installations.

Lightweight and Durability Benefits

Aluminum busbars in California offer remarkable lightweight properties that enhance ease of installation, making them a preferred choice among quality conductors near you. Their lower weight compared to traditional copper busbars simplifies handling and reduces the need for extensive structural support. Various bus bar options, including compact bus bars and flat bus bars, allow for versatile applications in electrical systems. Power bus bars designed with these lightweight materials ensure that even larger busbar sizes can be efficiently installed without compromising structural integrity.

Durability is another significant benefit of aluminum busbars. They are resistant to corrosion and environmental factors, ensuring a long lifespan even in challenging conditions. Grounding busbars made from aluminum maintain excellent conductivity over time, reducing the risk of failure in bus bar systems. Customized busbar solutions can be tailored to meet specific requirements, whether involving series busbars or busbar kits. These essential conductors provide reliability and performance, making them an ideal choice for various electrical installations throughout California.

Cost-Effectiveness for Electrical Installations

Aluminum Busbars in California provide a significant cost advantage compared to traditional copper bus options. The seamless bus pipe construction allows for effective bus packaging, reducing material waste and installation complexity. This is particularly beneficial for industries like transportation, where efficiency and reliability are paramount. The transition to aluminum not only meets electrical-grade aluminum standards but also ensures that high-quality aluminum is used for all metal parts. Organizations can save on overall project costs while receiving durable and effective solutions.

The versatility of aluminum busbars extends to various applications in electrical systems. Reliable aluminum metal allows for easier customization of busbar size reference and improves compatibility with switchgear busbars. This adaptability ensures that comprehensive conductive aluminum solutions can be tailored to meet specific needs across different sectors. With the ability to meet acoustical panels and other specialized requirements, aluminum offers a practical alternative that benefits businesses looking to optimize their electrical installations while minimizing costs.

Aluminum Busbar Capabilities and Specifications

Aluminum Busbars in California serve a critical role in modern electrical systems, providing efficient connectivity for various applications. They are widely utilized in commercial transportation and electric panels due to their lightweight nature and superior conductivity. Manufacturers often create these busbars from electrical-grade aluminum, ensuring high performance in demanding environments. Options such as aluminum round rod and aluminum coils are available for customization to meet specific load requirements. In transportation product manufacturing, aluminum housing is commonly paired with busbars to enhance durability and functionality. For those seeking reliable options, assessing local quality conductors near you will lead to reputable suppliers capable of delivering high-quality aluminum products suitable for any application.

Customization Options for Different Needs

Customization plays a crucial role in meeting the unique requirements of different industries. Aluminum Busbars in California can be tailored to specific applications such as power conversion bus systems or multi-motor panels. Utilizing various aluminum alloys allows manufacturers to achieve the right aluminum grade for specific needs, ensuring optimal performance. Industries such as conveyor equipment benefit from custom aluminum bus designs that facilitate efficient electrical distribution. The choice of a detailed aluminum alloy can greatly impact durability and conductivity, making it essential for businesses to work with Quality Conductors Near You.

The design of aluminum busbars can be adjusted to accommodate diverse equipment specifications. This includes choosing appropriate grade aluminum that meets the demands of high-performance applications. Custom aluminum panels can withstand varying loads while ensuring connectivity across various equipment. By focusing on lightweight yet durable metal, manufacturers can produce solutions that fit seamlessly into existing infrastructures. In California, businesses have access to quality conductors that cater to these specifications, enabling them to optimize their operational efficiency with tailored aluminum bus solutions.

Load Capacity and Electrical Conductivity

Aluminum busbars in California are designed to meet precise electrical specifications, ensuring their effectiveness in various applications. These busbars can support the power transportation needs of vertical elevators and parking structures, showcasing their robust load capacity. The selection of the exact aluminum grade plays a significant role in determining their performance. Using different aluminum alloys for construction allows for tailored solutions that cater to specific demands in the metal finishing industry and trailer construction.

Electrical conductivity is a critical factor when assessing the performance of aluminum busbars. High-quality aluminum sheets and flat bars are utilized to produce these conductors, providing reliable connections for panel boards and other electrical components. Selecting quality conductors near you ensures that the aluminum busbars meet the necessary standards for durability and efficiency. Ensuring that the correct aluminum grade is used can significantly enhance the overall performance and lifespan of your electrical systems.

Finding Quality Conductors Near You

Identifying reliable suppliers for aluminum conductors is essential for fulfilling various electrical infrastructure needs. Aluminum Busbars in California serve as a critical component in numerous applications, including HVACR equipment and outdoor applications, where durability and performance are paramount. Suppliers should offer top-grade aluminum alloys, such as 6063-T52 aluminum, ensuring that the products can withstand the rigors of diverse machinery and loads. Alongside aluminum busbars, quality providers should feature a range of metalworking products, including copper bars and stainless steel tubing, catering to specialized demands like metal etching and acoustic applications. Selecting a dependable source guarantees the integrity and effectiveness of the electrical systems where these materials are utilized.

How to Choose a Reliable Supplier in California

Selecting a reliable supplier for aluminum busbars in California necessitates thorough research. Look for suppliers known for their quality conductors near you, particularly those specializing in heavy-duty applications. Evaluate their product offerings, focusing on manufacturers like Chalco Aluminum and Graziadio GDA busbars. Ensure the supplier provides detailed specifications on material thickness and electrical performance. This information is crucial for ensuring that the aluminum busbars will meet the requirements of various electrical components, including circuit boards and load panels.

Verification of a supplier’s reputation plays a critical role in the decision-making process. Gather feedback from industry peers and review case studies highlighting the supplier’s capabilities. Attention should be paid to their experience in producing specialized items, such as slot load boards and junction outputs. A well-regarded supplier will also offer customization options tailored to your specific needs, allowing for optimal performance in your electrical systems. By focusing on these factors, you can confidently choose a supplier that meets your demands for aluminum busbars in California.

Conclusion

Aluminum busbars in California have become essential components in various electrical applications, providing reliable conductivity and efficient power distribution. As industries seek quality conductors near you, these busbars offer advantages over traditional brass products, including enhanced lightweight properties and durability. They play a vital role in supporting flex circuits and other innovative electrical solutions. The ability to customize these busbars ensures they meet specific needs in different environments, making them a preferred choice for many installations. Whether for commercial or industrial use, understanding the significance of aluminum busbars is key in optimizing performance and efficiency in electrical systems.

FAQS

What should I know about aluminum busbar manufacturing for various applications in California?

Aluminum busbar manufacturing involves the creation of electrical conductors that serve various industries, including HVACR equipment applications and transportation. High-quality aluminum busbars are crafted from top-grade aluminum alloys, such as electrical grade aluminum, ensuring optimal performance. It is essential to consider the specific aluminum alloys used, as well as the bar design and connections, when selecting busbars for applications like bus duct systems or insulated and grounding busbars. Manufacturers often provide inspection services to guarantee that aluminum busbars meet performance standards, making them ideal for uses ranging from electronics to conveyor equipment industries and beyond.

How do aluminum busbars impact energy efficiency in electrical systems for RVs and other transportation industries in California?

Aluminum busbars are essential components in electrical systems, as they play a significant role in energy efficiency. When using aluminum busbars, particularly those made from high-quality materials like 6063-T52 aluminum, you can achieve lower resistance and reduced power loss at high watts. In RVs and the transportation industry, aluminum busbars can optimize performance by ensuring efficient power distribution between components. Additionally, reliable distributors of bus bars typically offer a variety of products, including flexible busbars and standard busbars, which are crucial for various applications. Their design and installation can significantly affect the performance of electrical systems in settings such as parkings and front panels. Consideration of insulator busbars and proper cable management can further enhance overall system efficiency.

How can I find a distributor of flexible busbars and aluminum busbars in California for my electrical projects involving buses?

To locate a distributor of bus bars including flexible busbars & aluminum busbars in California, consider searching for metal suppliers that specialize in aluminum products such as 6063-t52 aluminum. Look for companies that offer a range of aluminum solutions, including aluminum pipe and acoustical products, as they can support your needs for various electrical applications involving buses.

What types of materials can be used for electrical busbars, and how do they compare to aluminum busbars?

When considering materials for electrical busbars, options include aluminum and copper. While aluminum busbars offer a variety of benefits such as lower weight and cost, copper busbars provide higher conductivity. Depending on the application, some projects may require insulated and grounding busbars, which can include aluminum plates or blue steel. Notably, 6063-t52 aluminum offers excellent structural properties, making it a popular choice. When sourcing these materials, you may want to find a distributor of flexible busbars to get the best options available.

How does the choice of aluminum busbar affect the performance and efficiency of electrical systems in California?

The choice of aluminum busbar depending on specific applications can significantly impact performance and efficiency. Aluminum busbars offers a lightweight and cost-effective solution compared to copper, particularly in large-scale installations. When looking for a distributor of flexible and insulated and grounding busbars, it’s essential to consider factors like conductivity and resistance to corrosion. Companies like GDA bus duct and Chalco aluminum production are known for their quality offerings, which can help in achieving optimal performance for your electrical systems.

How can I identify a reliable distributor of flexible, insulated and grounding busbars, including aluminum can options, in California?

To identify a reliable distributor of flexible, insulated and grounding busbars in California, consider checking local electrical supply stores, online directories, or industry-specific platforms. It’s also helpful to ask for recommendations from professionals in the field who may have experience with various suppliers. When looking for aluminum can products, ensure the distributor offers a range of options and specializes in high-quality busbars. Additionally, inquire about their experience with copper busbar twisting to ensure they have the expertise needed for your electrical projects.