Aluminum Busbar Manufacturing | Custom Fabrication Services

Aluminum busbar manufacturing plays a crucial role in the electrical industry, providing an efficient way to distribute electrical power. Custom fabrication services are essential for creating tailored solutions that meet specific project requirements. Using aluminum and its alloys, manufacturers can produce lightweight and durable busbars that outperform traditional copper alternatives. The manufacturing process involves precision metalworking techniques to ensure high-quality fabrications. Factories specializing in aluminum busbar production invest in advanced equipment and skilled labor, allowing for flexible designs and dimensions that cater to various applications. Overall, aluminum busbar manufacturing and custom fabrication services are vital for meeting the demand for reliable electrical busbars.

Aluminum Busbar Manufacturing | Custom Fabrication Services | Definition and Purpose of Aluminum Busbars

Aluminum busbars are critical components utilized to conduct electricity in various applications, especially within the automotive industry. These electrically conductive bars, typically fabricated from 6061-T6 aluminum, serve as a reliable alternative to heavier steel options. Their lightweight nature enhances efficiency, making them ideal for energy distribution systems. The process of aluminum busbar manufacturing encompasses various techniques, including milling and machining, which ensure precision and quality. Skilled manufacturers employ advanced machinery to produce bus bars tailored for specific needs, ensuring high performance in diverse environments.

Custom fabrication services are essential for meeting the unique requirements of each project involving aluminum busbars. These services allow for the adaptation of dimensions, shapes, and performance characteristics to suit different applications. Metal forming techniques play a significant role in this tailored approach, allowing manufacturers to create components that fit seamlessly into existing systems. The expertise required in aluminum busbar manufacturing goes beyond mere production; it requires a deep understanding of the materials and processes involved in creating high-quality bus bars that contribute to the overall reliability and efficiency of electrical systems.

Advantages of Using Aluminum in Busbar Fabrication

Aluminum offers significant benefits in busbar fabrication, particularly in industries such as aerospace, automotive, and rail transportation. The lightweight nature of aluminum compared to mild steel enhances the efficiency of bus systems, making them easier to install and manage in various applications. Advanced technologies like robot welding improve the precision and consistency of welded connections, ensuring high-quality performance. Utilizing aluminum in busways also results in lower energy losses due to its excellent conductivity, which is crucial for modern electrical systems.

The customization potential for aluminum busbars through tailored fabrication services allows manufacturers to meet specific design requirements. Custom Fabrication Services enable the production of complex shapes and sizes, accommodating unique project demands. This flexibility is particularly beneficial in progressive metal applications where design specifications vary greatly. The longevity and corrosion resistance of aluminum further enhance its suitability, making it a preferred choice for durable and reliable bus systems in diverse environments.

- Lightweight material reduces installation and handling costs.

- Excellent corrosion resistance extends the lifespan of busbars.

- Superior electrical conductivity minimizes energy losses.

- Customizable shapes and sizes cater to diverse project requirements.

- Enhanced resistance to thermal expansion maintains integrity over time.

- Eco-friendly material with high recyclability contributes to sustainability.

- Cost-effective production methods due to advanced fabrication technologies.

Aluminum Busbar Manufacturing Technology

The evolving landscape of Aluminum Busbar Manufacturing showcases significant advancements in custom fabrication services. Innovations in automation have streamlined production processes, enhancing efficiency while meeting precise specifications. Advanced tools, including sophisticated welding equipment endorsed by the American Welding Society, ensure the creation of high-quality connections. Techniques like metal stamping and specialized alloy formulations meet the demands of modern electronics and engineering applications. As the supply chain becomes increasingly integrated, manufacturers can effectively respond to the needs of various sectors, including those that rely on switches and other critical components. The emphasis on quality and innovation continues to shape the future of Aluminum Busbar Manufacturing and its custom fabrication services.

Innovations in Manufacturing Processes

Recent advancements in aluminum busbar manufacturing have significantly improved the efficiency and reliability of custom fabrication services. Innovations such as automated welding techniques and precision machining enhance the accuracy of custom busbar fabrication. These methods ensure that custom aluminum busbars meet stringent industry standards while optimizing aluminum busbar conductivity. As manufacturers adopt state-of-the-art technology, they can produce aluminum bus bars with reduced lead times and increased durability for various applications.

The integration of advanced materials and processes has transformed the landscape of busbar fabrication. Enhanced design software allows for better simulation and testing of custom aluminum bus products before production. This ensures that aluminum busbars perform optimally even under high current loads. By focusing on continuous improvement and embracing new technologies, companies can achieve higher quality standards and expand their service offerings in the realm of aluminum busbar manufacturing and custom fabrication services.

| Innovation | Description | Benefits |

|---|---|---|

| Automated Welding Techniques | Utilizing robotics and automation for welding processes | Improves welding precision and reduces labor costs |

| Precision Machining | Advanced machining techniques for exact dimensions | Ensures high accuracy and reduces material waste |

| Enhanced Design Software | Software for simulation and testing of designs | Facilitates optimization of products before production |

| Advanced Materials | Use of high-performance aluminum alloys | Increases conductivity and durability of busbars |

| Continuous Improvement Practices | Regular updates to processes and technologies | Ensures high quality and responsiveness to market needs |

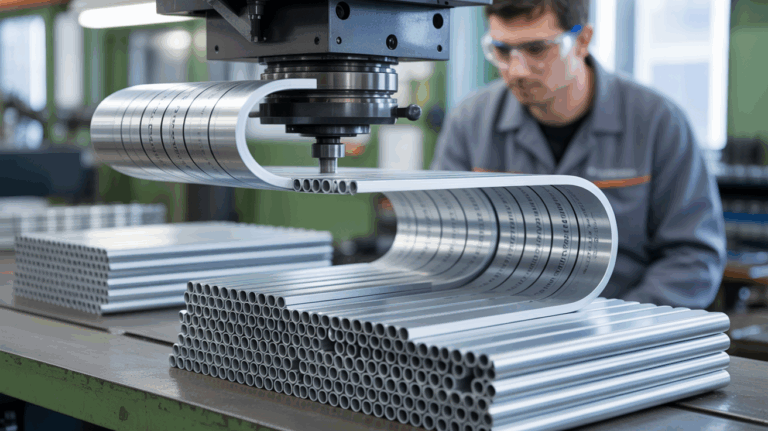

Key Equipment Used in Busbar Production

The busbar production department relies on various equipment to ensure the efficiency and precision of aluminum busbar manufacturing. Modern machinery includes CNC bending machines, shearers, and welding stations designed specifically for bus bar fabrications. These tools enable the designing and fabricating of custom made bus bars that meet specific project requirements. The integration of high-precision equipment facilitates the creation of high-quality aluminum bus bars that are essential for reliable electrical distribution.

High-quality copper or aluminum bus bars are often manufactured using specialized tools that enhance performance and durability. For instance, machines equipped for welding copper busbars provide robust connections that stand up to extensive electrical loads. The precise cutting and shaping of aluminum bars ensure that each product, whether it’s a welded busbar or a custom fabrication, meets industry standards for safety and efficiency. This focus on quality is crucial for clients seeking top aluminum bus solutions in their electrical systems.

Custom Fabrication Services

The process of Aluminum Busbar Manufacturing involves the creation of efficient custom busbars tailored to specific applications. Skilled professionals utilize advanced fabrication equipment in modern manufacturing facilities to produce high-quality aluminum components. Custom fabrications can encompass various designs, accommodating multiple busbar pieces to meet the demands of different projects. Utilizing aluminum materials ensures that these solid busbars remain lightweight yet durable, making them ideal for numerous busbar applications. For any next busbar project, selecting quality aluminum as a primary material is essential to achieving optimal performance and reliability in finished busbars.

Importance of Tailored Solutions in Busbar Production

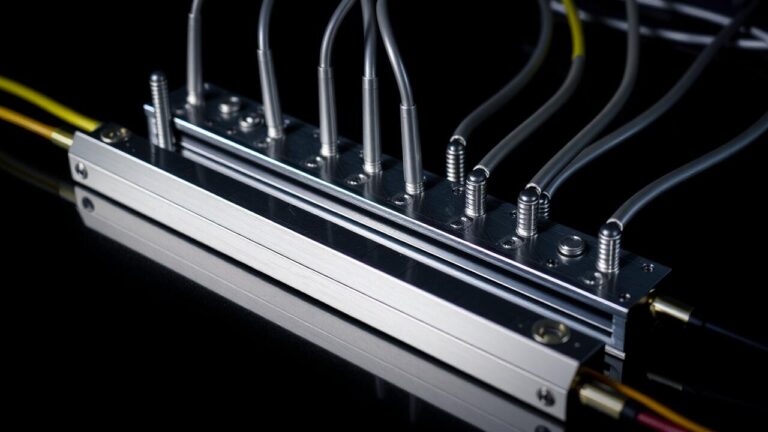

Tailored solutions are vital in the realm of Aluminum Busbar Manufacturing | Custom Fabrication Services. The ability to fabricate bus bars that meet specific requirements enhances the efficiency and reliability of busbar systems in various applications. Custom bus bars can be designed to accommodate different busbar sizes and shapes, ensuring they fit seamlessly within existing electrical infrastructures. This level of customization enables the production of specialized components, such as insulated busbars, electrode busbars, and busbar pads, which cater to unique operational demands and environmental conditions.

The use of aluminum strips in custom bus bar production offers significant benefits due to the metal’s lightweight nature and excellent conductivity. Each busbar piece can be designed to optimize performance, ensuring that side busbars and other configurations function effectively under load. Aluminum dependability allows manufacturers to create solutions that not only meet technical specifications but also withstand the rigors of industrial use. By investing in custom fabrication services, companies can achieve precision-engineered busbars tailored to their specific needs, maximizing both performance and return on investment.

Types of Custom Busbar Fabrication Services

Custom fabrication services in aluminum busbar manufacturing cater to a broad range of design fabrication needs. Options include flexible busbars that accommodate various configurations, such as center busbars and parallel busbars. Companies often seek high-grade aluminum for its lightweight and corrosion-resistant properties, while others might consider high strength aluminum for demanding applications. The choice between aluminum and copper bus bars often depends on the specific requirements of the project, including electrical conductivity and weight considerations.

For those requiring larger dimensions, extra-large busbars and modular bus bar designs offer versatility in assembly and installation. High-quality bus bars, whether made from aluminum or copper, ensure optimal performance in electrical systems. The ability to customize each component allows manufacturers to meet unique specifications, thus enhancing the functionality of the overall electrical infrastructure. Aluminum Busbar Manufacturing | Custom Fabrication Services provide tailored solutions to support a variety of industrial needs.

Aluminum Busbar Capabilities

Aluminum busbars play a crucial role in efficient electrical power distribution systems, whether as a single busbar system or a more complex double busbar system. Emphasizing the need for superior busbar solutions, manufacturers often engage skilled metal craftsmen who utilize advanced industrial machinery for metal forming and fabrication. Custom fabrication services are essential for meeting specific project requirements, whether it involves low volume busbar production or large-scale fabrication projects. Various busbar interfaces are designed to enhance connectivity and performance, ensuring that each custom fabrication solution meets industry standards. The integration of custom progressive metal stamping techniques further enriches the capabilities of aluminum busbar manufacturing, resulting in highly effective and tailored solutions for diverse applications.

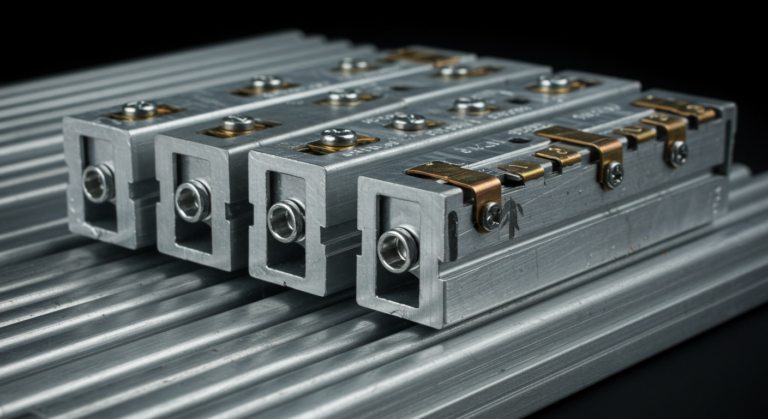

Dimensions and Specifications of Aluminum Busbars

Aluminum busbars are available in a variety of dimensions, tailored to meet the specific requirements of various applications. The use of 6063-T52 aluminum alloy ensures optimal performance, particularly in high-capacity bus bars designed for both AC and DC systems. Bar manufacturers utilize advanced fabrication methods and hydraulic metalworking machines to produce these components, ensuring precise dimensions that align with industry standards. Custom fabrication services play a crucial role in providing panels and bus bars that cater to unique specifications, enhancing the overall efficiency of electrical systems.

The specifications of aluminum busbars encompass critical attributes, including thickness, width, and length, which can be customized to fit the needs of the final assembly bus. Automation equipment is often employed in the manufacturing process to streamline production and maintain consistency across batches. A range of bus bars is available, with options that accommodate various electrical loads and installation environments. Overall, attention to these dimensions and specifications is essential for ensuring reliability and effectiveness in electrical distribution systems.

Performance Characteristics and Limits

Aluminum busbars are essential components in electrical bus systems, designed to efficiently conduct electricity with minimal resistance. The performance characteristics of these busbars largely depend on factors such as bar design and the purity of the aluminum used. High conductivity, specifically from pure aluminum, allows for effective energy distribution across various applications, making them ideal for industrial fabricators and sectors that require reliable power management. The incorporation of advanced machinery during Aluminum Busbar Manufacturing | Custom Fabrication Services enhances precision in dimensions and helps achieve custom solutions tailored to specific project needs.

Limitations in performance can arise from factors such as temperature variations and environmental influences. The durability of aluminum busbars can also be affected by the quality of powder coating services, which serve to protect against corrosion and wear in industrial settings. Custom-fitted bus boots and effective integration into distribution panels can further optimize the performance of the busbars while ensuring adherence to safety standards. The investment in skilled labor and expertise during the manufacturing process is crucial for overcoming these limits and delivering high-quality rhi busbars that meet the demands of various industries.

- High conductivity from pure aluminum ensures efficient energy distribution.

- Advanced design enhances performance and flexibility for various applications.

- Temperature fluctuations can impact busbar effectiveness.

- Powder coating quality is vital for corrosion resistance and longevity.

- Custom-fitted components enhance integration and overall functionality.

- Skilled labor is essential for maintaining high manufacturing standards.

- Regular inspections can help identify and mitigate potential performance issues.

Investment and Know-How in Aluminum Busbar Manufacturing

Successful aluminum busbar manufacturing relies heavily on investment in skilled labor and advanced technology. Experienced industrial fabricators today understand the importance of using certified manufacturers to produce high-quality metallic conductors that meet the demanding specifications of electronic industries. The integration of engineering options like lightweight design and diverse machining processes, including automatic robot welding and assembly, enhances the efficiency and precision of production. Utilizing solid works technologies allows for the creation of specific designs tailored to client needs. Comprehensive custom fabrication services ensure that every aluminum busbar meets the necessary performance characteristics and dimensions, positioning manufacturers for success in a competitive market.

Importance of Skilled Labor and Expertise

Skilled labor plays a vital role in Aluminum Busbar Manufacturing | Custom Fabrication Services. Professionals in this field understand the intricacies involved in designing busbars to meet many specifications. Their expertise ensures proper hardware placement, optimizing the assembly process for high-power equipment. These skilled workers leverage advanced technologies and a versatile machine to achieve complete design capabilities, crucial for meeting the diverse needs of clients.

Expertise in Aluminum Busbar Manufacturing | Custom Fabrication Services allows for effective management of complex projects. The ability to create parts with both simple design and intricate detailing ensures that all components function seamlessly within the operating environment. Assembling busbars on a rail system demands precision, making skilled labor indispensable. Each crafted piece contributes to the reliability and efficiency of electrical systems, highlighting the importance of trained professionals in this industry.

Return on Investment for Custom Fabrication Services

Investing in Aluminum Busbar Manufacturing through Custom Fabrication Services can significantly enhance operational efficiency. Tailored solutions enable businesses to meet specific production needs, ensuring bus bars are designed according to precise project specifications. This customization often includes innovative designs that facilitate convenient transportation and installation, especially for water-cooled bus bars. Quality craftsmanship is essential, as skilled craftsmen utilize advanced techniques such as automatic copper forming to create products that withstand the rigors of various applications.

Cost savings are a crucial aspect of evaluating the return on investment from these custom services. By focusing on the unique requirements of each project, companies can optimize their production capabilities while minimizing waste. Clean design enhances both aesthetic appeal and functionality, promoting better integration into panel boards. The initial investment in specialized fabrication pays off through improved performance and durability, making Aluminum Busbar Manufacturing a smart choice for businesses looking to thrive in competitive markets.

Comprehensive Busbar Fabrication Services

Aluminum busbar manufacturing utilizes custom fabrication services to deliver high-quality work tailored to specific engineering capabilities. This process involves producing essential components like bus boots designed to handle various loads and applications, ensuring reliability in electrical installations. A streamlined and efficient supply chain facilitates the timely delivery of these products, supporting the demands of various industries. By focusing on precision in the fabrication of aluminum bars, manufacturers can achieve optimal performance and longevity, critical for effective electrical distribution systems.

| Busbar Type | Material | Load Capacity (Amps) | Applications |

|---|---|---|---|

| Flat Busbar | Aluminum | 1000A | Power distribution, electrical panels |

| Round Busbar | Aluminum | 800A | Transformers, overhead power lines |

| Bus Duct | Aluminum | 2000A | Data centers, industrial applications |

| Insulated Busbar | Aluminum | 1500A | Substations, renewable energy systems |

Conclusion

Aluminum busbar manufacturing stands as a critical component in modern electrical distribution systems, offering tailored solutions through custom fabrication services. The ability to design bars that meet specific dimensions and performance characteristics ensures they can handle current loads efficiently and reliably. Integration of advanced manufacturing processes and skilled labor enhances the overall quality and performance of these busbars. Investing in aluminum busbar manufacturing not only improves system reliability but also optimizes operational efficiency, leading to significant returns on investment. Emphasizing customized solutions allows for adaptability in various applications, solidifying the role of custom fabrication services in meeting the evolving needs of the industry.

FAQS

What are the key elements of aluminum busbar manufacturing technology that influence investment and know-how in custom fabrication solutions?

The key elements of aluminum busbar manufacturing technology include the choice of materials, such as 6063-t52 aluminum, which offers advantages like pure aluminum conductivity. Investment in advanced techniques, like custom progressive metal stamping and metal forming and fabrication, is essential for designing and fabricating custom made bus bars. Additionally, a knowledgeable factory that specializes in the manufacture of custom solutions can significantly enhance the quality of bus bar fabrications, including welded busbars and ac/dc bus bars, ensuring optimal performance in electrical systems.

How does aluminum busbar manufacturing technology impact the investment and know-how in custom fabrication solutions for various metals?

Aluminum busbar manufacturing technology plays a significant role in determining the level of investment and know-how required for custom fabrication solutions. It involves the use of advanced processes and techniques to work with materials such as 6063-T52 aluminum, which offers excellent strength and corrosion resistance. Companies utilize copper busbar products in conjunction with aluminum to meet specific electrical conductivity needs. Additionally, custom fabrication solutions may involve services like custom progressive metal stamping and metal forming and fabrication that ensure the production of high-quality bus bar fabrications, leading to a complete assembly tailored to customer specifications.

How does understanding aluminum busbar manufacturing technology contribute to the investment and know-how needed for effective bus bar fabrications?

Understanding aluminum busbar manufacturing technology is crucial as it directly influences investment decisions and enhances aluminum bus bar know-how. Companies that are well-versed in this technology gain a competitive advantage in the custom fabrication market for various metals, including those that utilize techniques like custom progressive metal stamping and metal forming and fabrication. For instance, using 6063-t52 aluminum offers a lightweight yet durable option for manufacturers looking to create custom solutions in busbar ifab applications.

How does the investment and know-how in aluminum busbar manufacturing technology affect the production of custom solutions in the flat metal industry?

The investment and know-how in aluminum busbar manufacturing technology are crucial for efficiently producing high-quality aluminum bus bars. This technology plays a significant role in the ability to manufacture custom solutions using techniques such as custom progressive metal stamping, which is essential in the metal forming and fabrication process. Understanding this technology ensures that manufacturers can meet specific requirements while maintaining cost efficiency in producing flat metal components.

How does the aluminum busbar manufacturing technology play a role in enhancing the investment and know-how for custom progressive metal stamping and fabrication?

The aluminum busbar manufacturing technology significantly influences the investment decisions and the required aluminum busbar know-how for effective custom progressive metal stamping, as well as other metal forming and fabrication processes. By understanding these factors, manufacturers can better allocate resources and refine their techniques to produce high-quality aluminum bus bars.

How does the aluminum busbar manufacturing technology influence the investment and know-how required for custom progressive metal stamping and metal forming and fabrication?

The aluminum busbar manufacturing technology significantly affects the investment and know-how required for custom progressive metal stamping and metal forming and fabrication. By utilizing advanced techniques and processes associated with aluminum busbar know-how, manufacturers can optimize production efficiency and enhance custom solutions. This investment in technology not only improves the overall quality of aluminum bus bars but also streamlines the fabrication process, leading to better outcomes in the metal forming and fabrication industry.

How does the investment and know-how in aluminum busbar manufacturing technology affect the development of aluminum bus bar solutions in custom progressive metal stamping and general fabrication?

The investment and know-how in aluminum busbar manufacturing technology greatly influence the development of effective aluminum bus bar solutions. By leveraging aluminum’s properties and understanding custom progressive metal stamping, manufacturers can optimize their metal forming and fabrication processes, ensuring high-quality outputs that meet specific industry demands.

How does aluminum busbar manufacturing technology enhance the investment and know-how in custom progressive metal stamping and metal forming and fabrication processes?

Aluminum busbar manufacturing technology significantly enhances the investment and know-how for custom progressive metal stamping and metal forming and fabrication processes by providing insight into efficient production techniques and material characteristics. This understanding allows manufacturers to optimize their use of aluminum, which can improve the overall quality and cost-effectiveness of custom solutions in these areas, ensuring that the final products meet industry standards and customer expectations.

How does the aluminum busbar manufacturing technology shape the necessary investment and know-how for projects involving custom progressive metal stamping and metal forming and fabrication?

The aluminum busbar manufacturing technology is crucial as it informs the level of investment and the specific aluminum busbar know-how required for successful projects. This technology not only facilitates the efficient production of aluminum components but also ensures that manufacturers can effectively engage in custom progressive metal stamping and metal forming and fabrication processes, ultimately resulting in high-quality outcomes.

How does aluminum busbar manufacturing technology influence the investment and know-how necessary for custom progressive metal stamping in the metal forming and fabrication industry?

The aluminum busbar manufacturing technology plays a crucial role in determining the investment and know-how required for effective custom progressive metal stamping. This technology not only enhances the efficiency of the processes involved but also allows for the production of high-quality aluminum busbar solutions, which are essential for various applications in metal forming and fabrication. As companies invest in better aluminum busbar know-how, they can improve their overall production capabilities and meet the needs of customers more effectively, leading to innovative solutions using aluminum and other metals.