Aluminum Busbar Manufacturing: Precision Fabrication from AP Precision Metals

When it comes to high-performance aluminum busbar manufacturing, AP Precision Metals leads the way with superior fabrication capabilities, consistent quality, and unmatched industry expertise. Whether you’re designing power systems for electric vehicles, renewable energy installations, or complex industrial equipment, our aluminum busbars are engineered to meet your exact electrical and mechanical requirements.

Why Choose Aluminum for Busbar Applications?

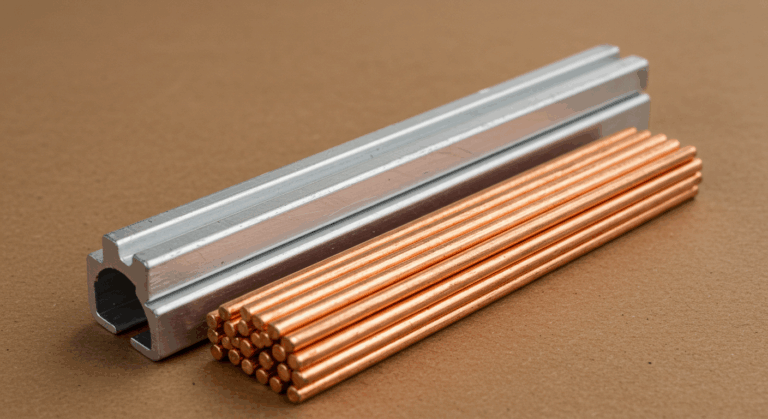

Aluminum busbars are increasingly used in modern electrical systems for their excellent balance of performance, affordability, and weight. Key benefits include:

- Lower Weight: Aluminum is significantly lighter than copper, reducing total system weight and easing installation.

- Cost-Efficiency: Its lower raw material cost helps control budgets without sacrificing electrical performance.

- Good Conductivity: Aluminum conducts electricity efficiently and is suitable for a wide range of voltage applications.

- Corrosion Resistance: A natural oxide layer protects aluminum from corrosion, especially in outdoor or industrial environments.

- Thermal Management: High thermal conductivity makes aluminum busbars excellent at dissipating heat in high-load systems.

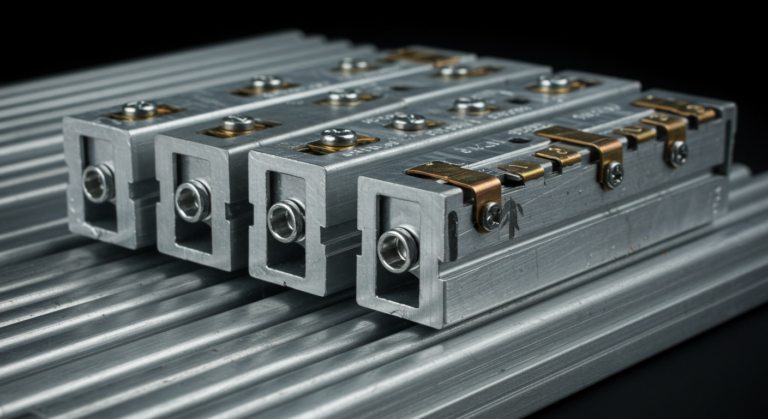

Our Aluminum Busbar Manufacturing Capabilities

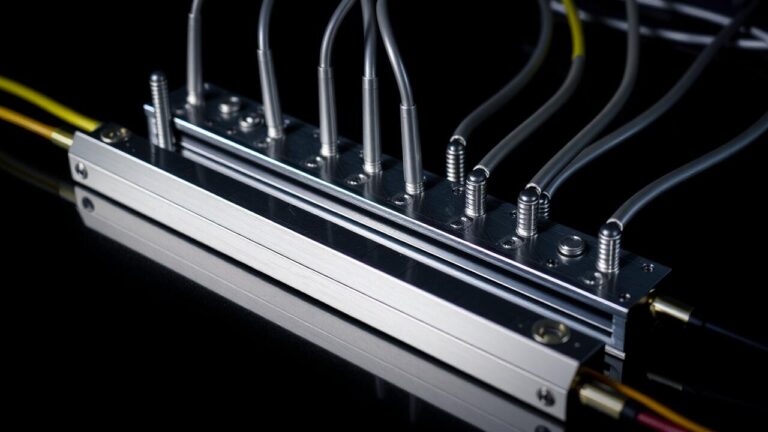

At AP Precision Metals, we manufacture aluminum busbars with exacting standards and advanced technology. From prototyping to full-scale production, our facility supports a wide range of services:

- CNC Precision Cutting: Delivering clean, consistent shapes with minimal material waste.

- Bending & Forming: Custom bends and dimensions tailored to your system layout and load requirements.

- Punching & Stamping: High-accuracy tooling for holes, slots, and mounting patterns.

- Surface Finishing: Offering smooth finishes, anodizing, or powder coating as needed for conductivity or protection.

- Insulating & Coating: Options for insulation, shrink wrap, or epoxy coatings for safety and compliance.

Industries We Serve

Our aluminum busbar manufacturing supports a wide range of industries, each with unique requirements and standards:

- Electric Vehicles (EVs): Lightweight, efficient busbars for battery management and onboard power systems.

- Renewable Energy: Durable aluminum busbars for solar, wind, and energy storage installations.

- Power Distribution: Custom busbars for switchgear, transformers, and distribution panels.

- Telecommunications: Efficient and compact solutions for backup power and data center infrastructure.

- Industrial Equipment: High-load electrical conductors for motors, controls, and automated systems.

Custom Design and Engineering Support

We partner with engineers, designers, and procurement teams to manufacture aluminum busbars that align with your design goals. Our team assists from concept through production to ensure the right material thickness, configuration, and finish for your application.

Our Quality Commitment

AP Precision Metals is committed to providing consistent, reliable, and high-performing aluminum busbars. We implement rigorous quality control processes and maintain certifications to ensure every component meets client specifications and industry standards.

Contact Us for Custom Aluminum Busbar Manufacturing

If you’re seeking dependable, high-quality aluminum busbar manufacturing for your next project, AP Precision Metals has the equipment, expertise, and capacity to deliver. Contact us today to discuss your requirements and learn how we can support your goals with custom aluminum busbar solutions.