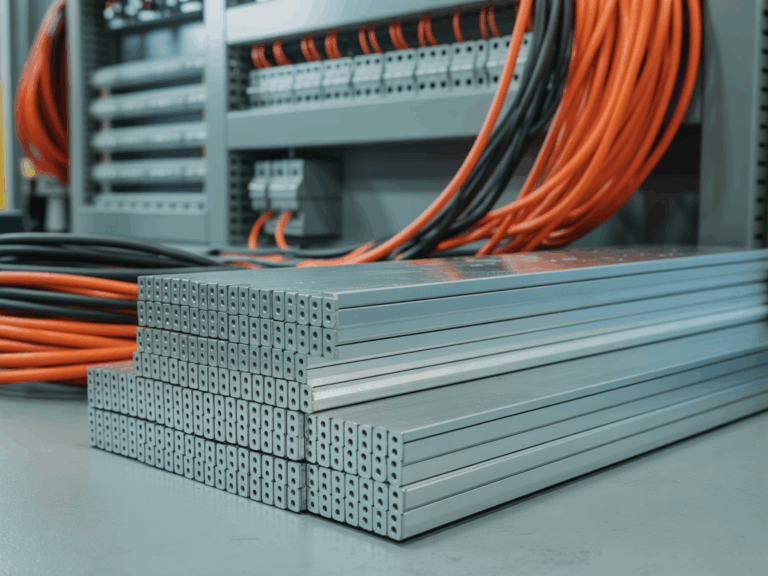

Exploring Aluminum Busbars: Types, Benefits, and Industrial Applications

In today’s rapidly advancing technological landscape, efficient and reliable electrical systems are paramount. One of the key components that play a crucial role in ensuring the efficiency and reliability of these systems is the aluminum busbar. This article delves into the significance of aluminum busbars, their benefits, types, applications, and why they are preferred over other materials in various industries.

What are Aluminum Busbars?

Aluminum busbars are metallic strips or bars made of aluminum used to conduct electricity within switchboards, distribution boards, substations, and other electrical apparatus. These busbars are essential for the efficient distribution of electrical power and are known for their durability and conductivity.

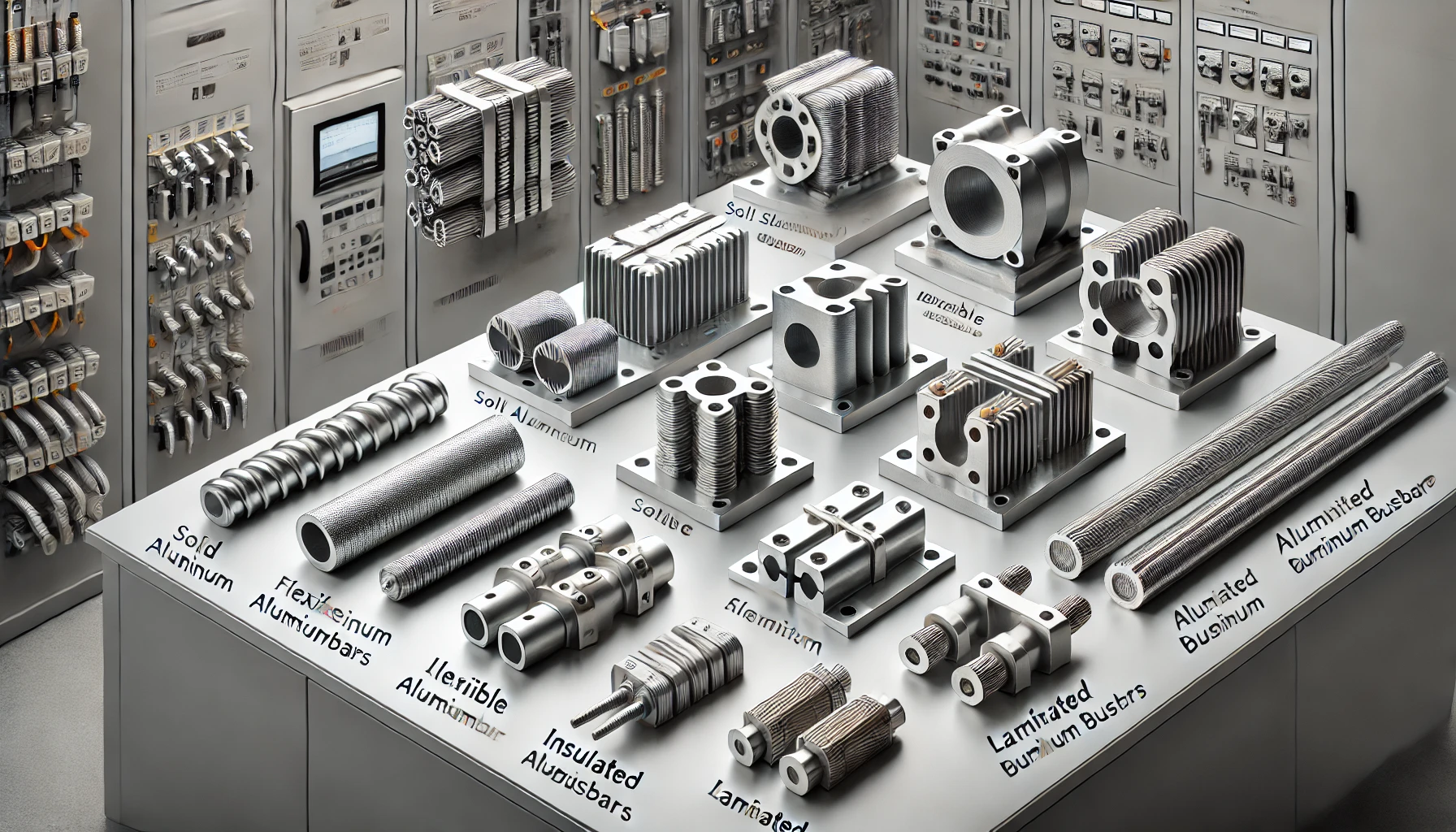

Types of Aluminum Busbars

Aluminum busbars come in various types, each designed to meet specific needs and applications. The primary types include:

Solid Aluminum Busbars

These are the most common type, featuring a solid rectangular or cylindrical shape. They are widely used in high-current applications due to their excellent conductivity and durability.

Flexible Aluminum Busbars

Made from multiple layers of thin aluminum strips, these busbars are designed to be flexible. They are ideal for applications that require frequent movement or where space constraints make rigid busbars impractical.

Insulated Aluminum Busbars

These busbars are coated with an insulating layer to prevent accidental contact and reduce the risk of short circuits. They are commonly used in environments where safety is a priority.

Laminated Aluminum Busbars

Laminated busbars consist of multiple layers of aluminum separated by insulating materials. They offer superior electrical performance and thermal management and are often used in high-frequency and high-power applications.

Extruded Aluminum Busbars

These busbars are manufactured through an extrusion process, allowing for complex shapes and custom designs. They are used in applications requiring precise dimensions and high mechanical strength.

Benefits of Aluminum Busbars

Aluminum busbars offer a range of benefits that make them a preferred choice in various industries. These benefits include:

High Electrical Conductivity

Aluminum has excellent electrical conductivity, which allows for efficient transmission of electricity with minimal power loss. This makes aluminum busbars ideal for high-current applications.

Lightweight

Aluminum is significantly lighter than copper, the other common material used for busbars. This weight advantage makes installation and handling more accessible and reduces the structural load on supporting systems.

Cost-Effective

Aluminum is more abundant and less expensive than copper, making aluminum busbars a cost-effective solution for electrical distribution systems. This cost savings is particularly significant in large-scale projects.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that resists corrosion, making aluminum busbars suitable for use in harsh environments. This enhances the longevity and reliability of electrical systems.

Thermal Performance

Aluminum has excellent thermal conductivity, which helps dissipate heat effectively. This thermal management capability is crucial in preventing overheating and ensuring the safe operation of electrical systems.

Flexibility and Customization

Aluminum busbars can be easily fabricated into various shapes and sizes, allowing for customized solutions that meet specific design requirements. This flexibility is beneficial in complex electrical systems with unique spatial constraints.

Recyclability

Aluminum is highly recyclable, making aluminum busbars an environmentally friendly choice. Recycling aluminum requires significantly less energy compared to producing new aluminum, contributing to sustainability efforts.

Mechanical Strength

Despite being lightweight, aluminum offers good mechanical strength, ensuring the durability and stability of busbars in demanding applications. This strength-to-weight ratio is particularly advantageous in the aerospace and automotive industries.

Applications of Aluminum Busbars

The versatility and benefits of aluminum busbars make them suitable for a wide range of applications across various industries. Some of the common applications include:

Power Distribution Systems

Aluminum busbars are extensively used in power distribution systems for commercial and industrial buildings, ensuring efficient and reliable electricity transmission.

Renewable Energy Systems

In solar and wind energy systems, aluminum busbars connect and distribute power generated by renewable sources. Their lightweight and corrosion-resistant properties are particularly advantageous in outdoor installations.

Automotive Industry

Electric vehicles (EVs) and hybrid vehicles use aluminum busbars for their battery and electrical systems. The lightweight nature of aluminum helps improve the overall efficiency and performance of the vehicles.

Aerospace Industry

Aluminum busbars are used in aircraft electrical systems in the aerospace industry. Their lightweight and high-strength properties contribute to weight reduction and enhanced fuel efficiency.

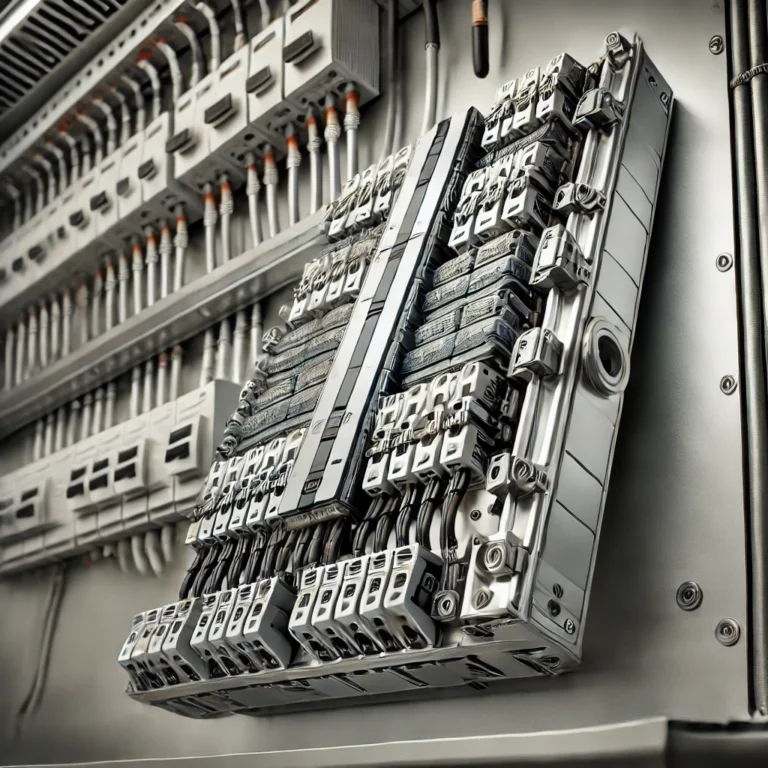

Electrical Panels and Switchgear

Aluminum busbars are integral components of electrical panels and switchgear, providing a reliable means of distributing electrical power within these systems.

Telecommunication Equipment

Aluminum busbars are used in telecommunication equipment to manage and distribute electrical power efficiently, ensuring the reliability of communication networks.

Conclusion

Aluminum busbars are indispensable components in modern electrical systems, offering a range of benefits that include high electrical conductivity, cost-effectiveness, corrosion resistance, and excellent thermal performance. With various types available, such as solid, flexible, insulated, laminated, and extruded busbars, aluminum busbars can be tailored to meet the specific needs of different applications. From power distribution systems and renewable energy installations to the automotive and aerospace industries, aluminum busbars play a crucial role in ensuring efficient and reliable electricity transmission and distribution. As industries continue to evolve, the demand for aluminum busbars is expected to grow, further solidifying their importance in the electrical engineering landscape.